FP2000 / FP3000

The latest packaging technology. The modular design enables machine concepts tailored to your needs.

Film tension

Simplest assembly with film rolls: Our pneumatic film recording.

Just press a button and the film roll is ready for use.

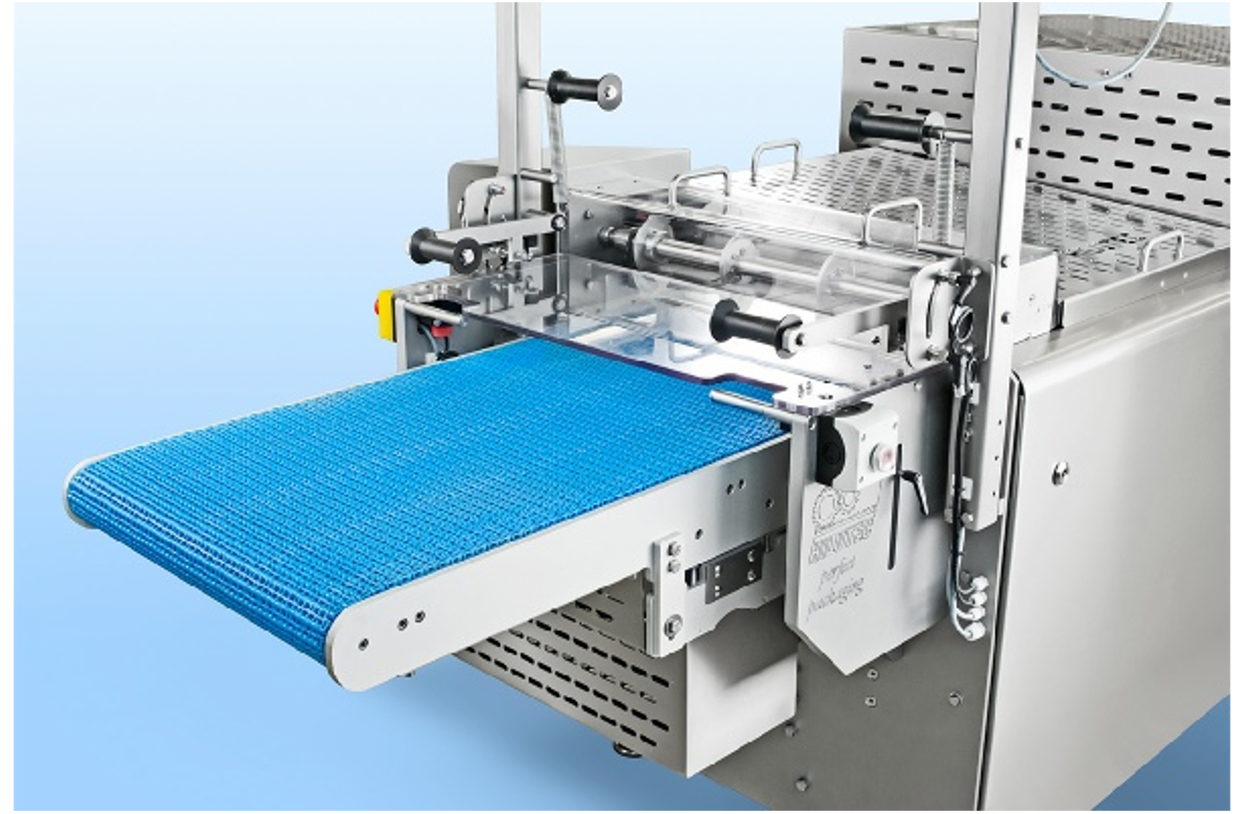

Intralox Auslaufgurt

No compromise! Conveyor technology from the market leader.

Also for the discharge conveyor only the highest quality materials available on the market is used by default. High performance

Available in almost all latitudes and longitudes.

Sandwich Heating

Increased efficiency through faster sheet heating. Our optional heating systems, such as the separate preheating or the sandwich Heating allow the heating of the lower film, even before it is drawn into the mold. In traditional construction, the lower foil is heated until the mold.

Labeling systems

With the labeling systems we use labels may be stuck both on the packing and below the packing.

With automatic Leerpackungs-

- as transverse

and / or longitudinal design

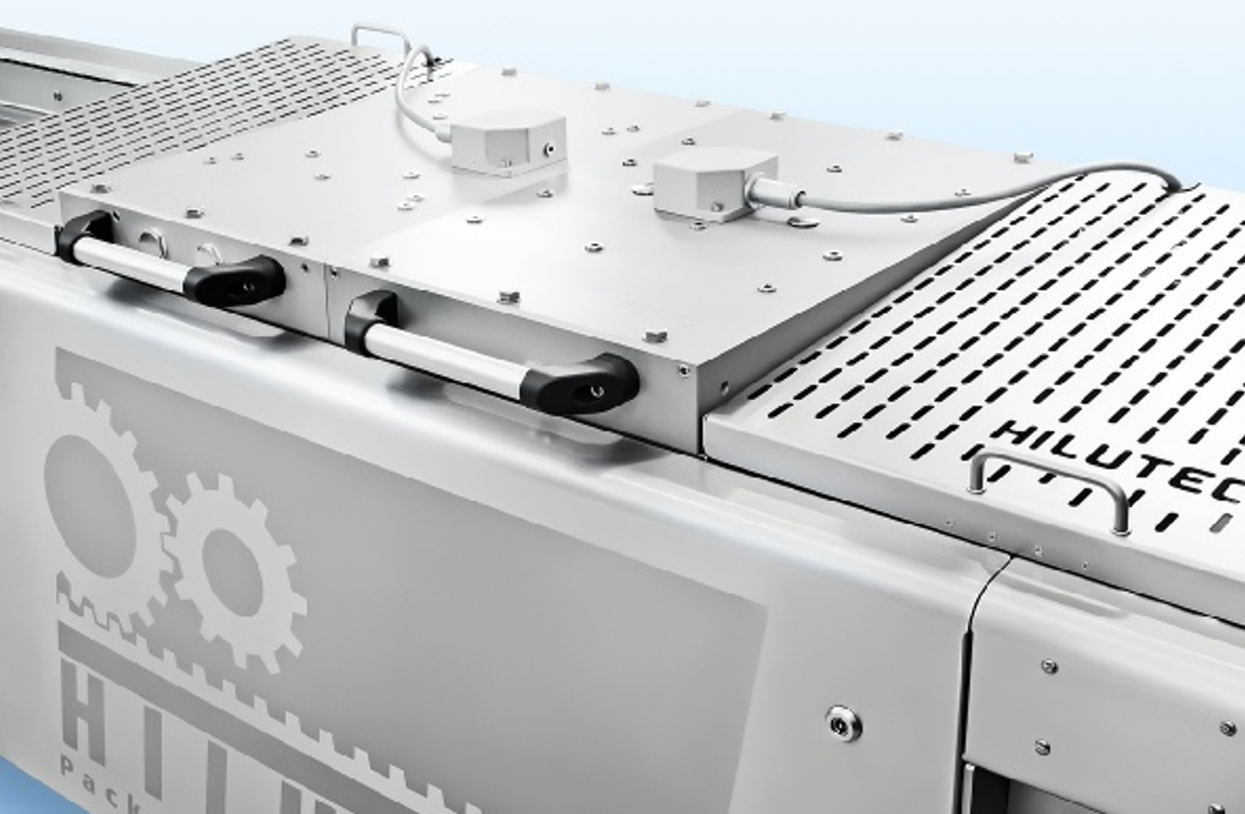

Easy Cleaning

The cleaning of our machines: simple and easy to clean design. Even the inner life: quickly and safely reachable by folding side panels. Our design meets the highest hygiene standards.

Printing Systems

With printer assembly according to customers request, also flexibly to Verfahrrahmen. Etc for printing text, barcodes, graphics, prices ..

Directly on film or on paper labels.

Aircleaner and

Dispensers of liquids

Optional accessories made by HILUTEC.

For customers who want to pack your products into liquids.

FP 2000

| Film width | 360-560 mm |

| Off Length | 180-600 mm |

| Machine Length | 5000-6000 mm (depending on conveyor) |

| Machine Height | 2040 mm |

| Drawing Depth Max | 190 mm |

| Roll Diameter | Max 500 mm |

FP 2000 XXL –

| Film width | 360-560 mm |

| Off Length | 180-600 mm |

| Machine Length | 7000-10500 mm (depending on conveyor) |

| Machine Height | 2040 mm |

| Drawing Depth Max | 190 mm |

| Roll Diameter | Max 500 mm |