|

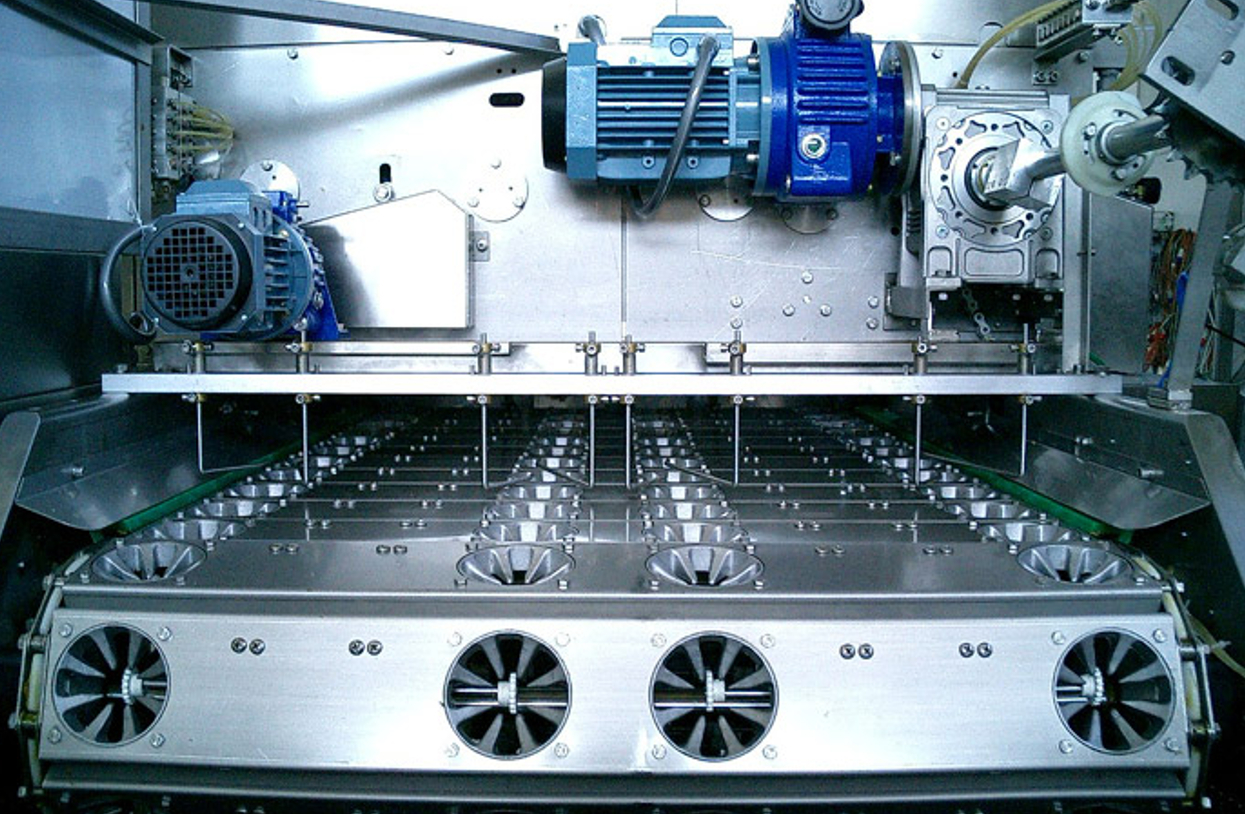

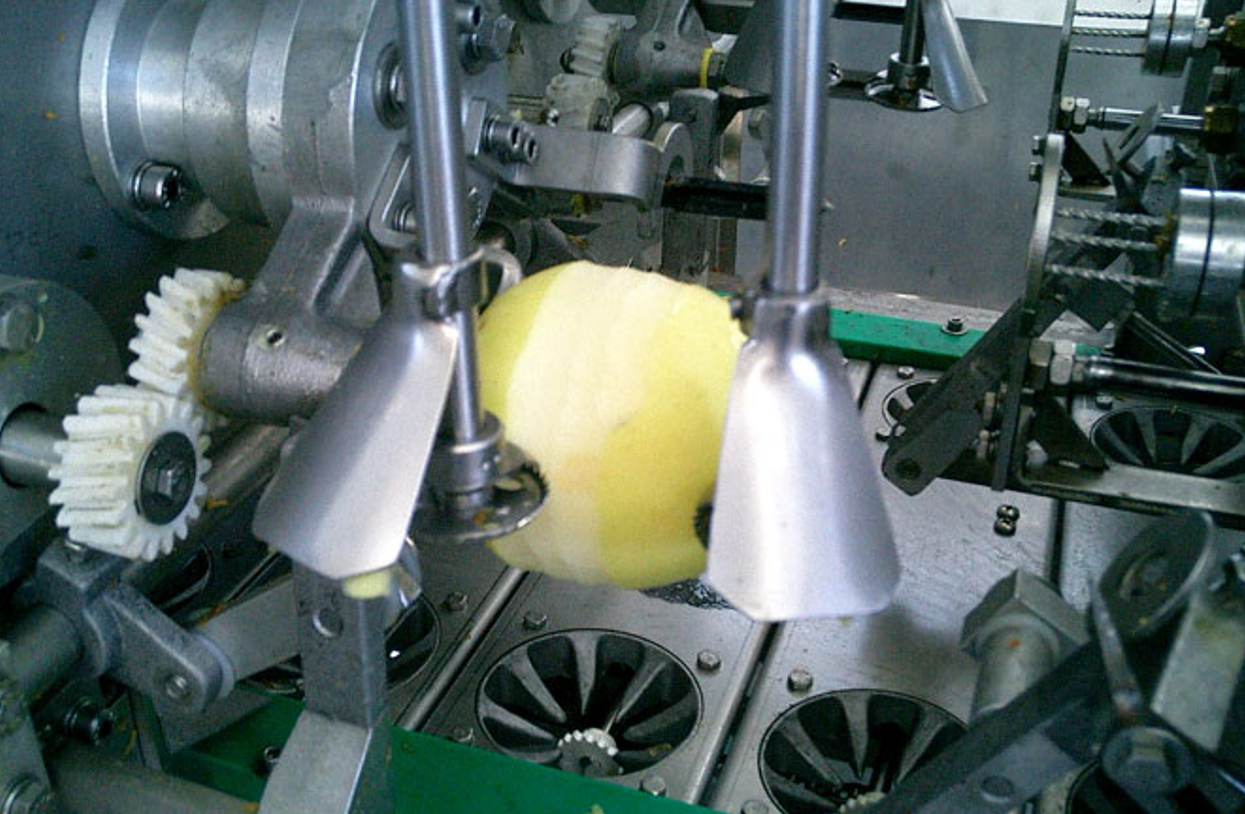

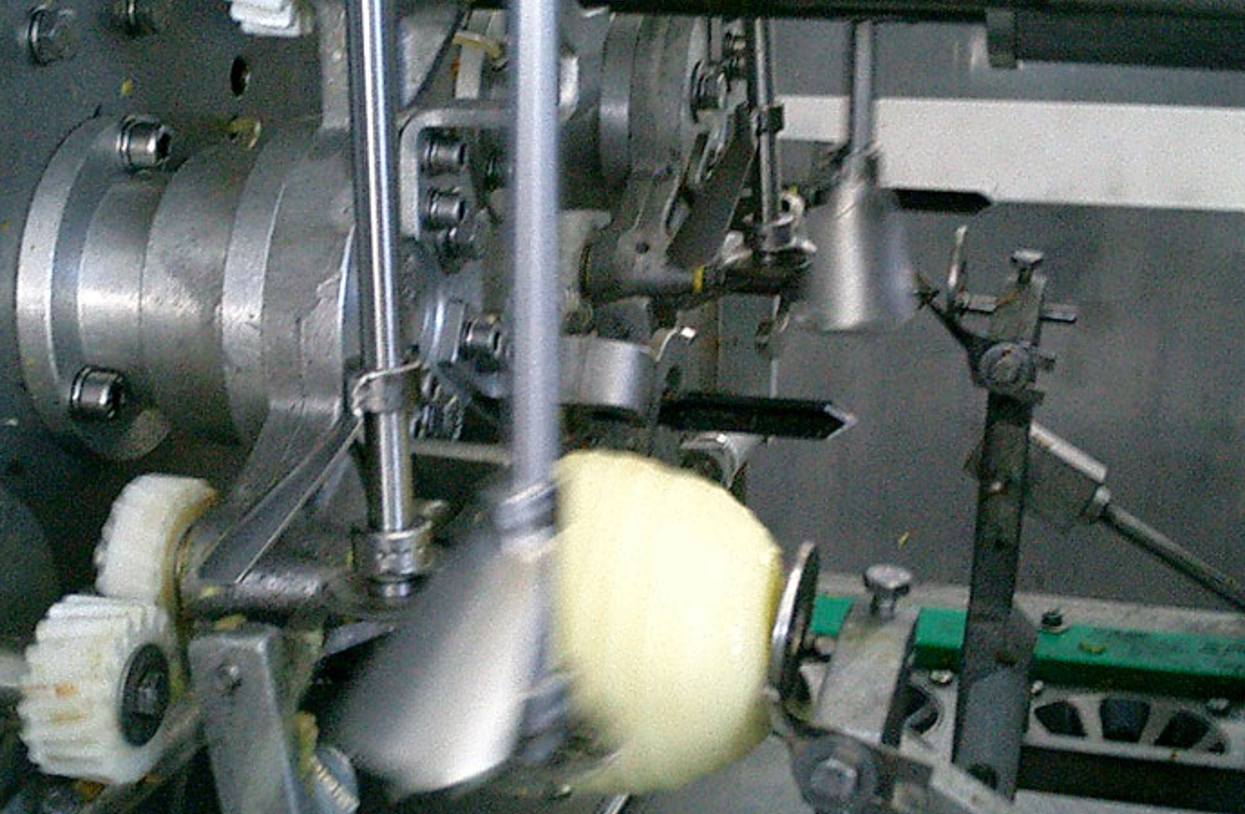

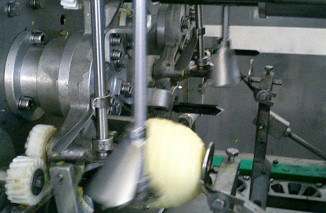

With a completely automatic procedure, PDS/R peels, cores and can cut the apples in different shapes at a maximum speed of 100 fruits for minute (according to the model) with the guarantee to get high quality product and leaving fruit characteristics totally unchanged – structure, character, flavour. In reason of specific demands, each peeler can be equipped with the right device for the cut in segments or for the cut in rings (slices) or as well as it can mount an application allowing the cut in irregular dice or even in perfect cylinders (i.e. special feature of processing): the substitution of a station with the other can be realized quickly and without the need of particular tools. Some solutions that can improve your production. Three formats of cut: segments to get from 2 up to 16 equal parts; slices with adjustable thickness, ranging from 3 up to 15 mms; irregular dices. Double head of skinning for a profile more delineated. New finishing lines in fact of productivity and aesthetics of the ended product. From the production of small lot to the industrial processing: in this range you can find the machine that allow you the right flexibility. PDS/R excels with 3 cut options, technical perfection and good peeling performances. Equipped – in its basic version PD of modern control technologies and hi-tech components that were before reserved exclusively to the large processing lines. (description of the cycle of job) The process itself can also be interrupted to the simple coring leaving the apple whole. The adopted solutions and the technology applied on the P.D.S. / R. allow an exceptional quality of the job with minimum waste amount, aesthetic look of the product and assurance that fruit is not contaminated during any of the processing phase. The peeler is provided of centralized lubrication timer driven to guarantee the best long-lasting operating conditions. Board panel featuring an on/off and a jog-switch button for isolated movements. All the PDS/R are supplied with a set of spareparts, a user manual, pneumatic and electric schemes. Peeling and partial peeling |

Coring

The coring is developed through a cylindrical hole that removes the core only of the apple.

Coretubes are available in different dimensions to optimize the yield depending upon fruit size.

16 mms. diam. for small apples

18 mms. diam. for middle apples

20 / 30 mms. diam. for big apples

Seed cell

Seed cell blade remove the spherical hollow in the heart of the apple after that it has been cored. Of course the blades is available in various dimensions, better fit fruit size.

Segments and half segments

Minimum of obtainable parts: 2

Maximum obtainable parts: 16

Knives are radially positioned on the cutting disk: the dimensions of the segments depends exclusively upon the number of employed knives.

Slices and half rings

Minimum thickness: 3 mms.

Maximum thickness: 15 mms.

The cutting disk is combined with special spacer to be inserted between the disk and the blade in such a way to always get different thickness of cut.

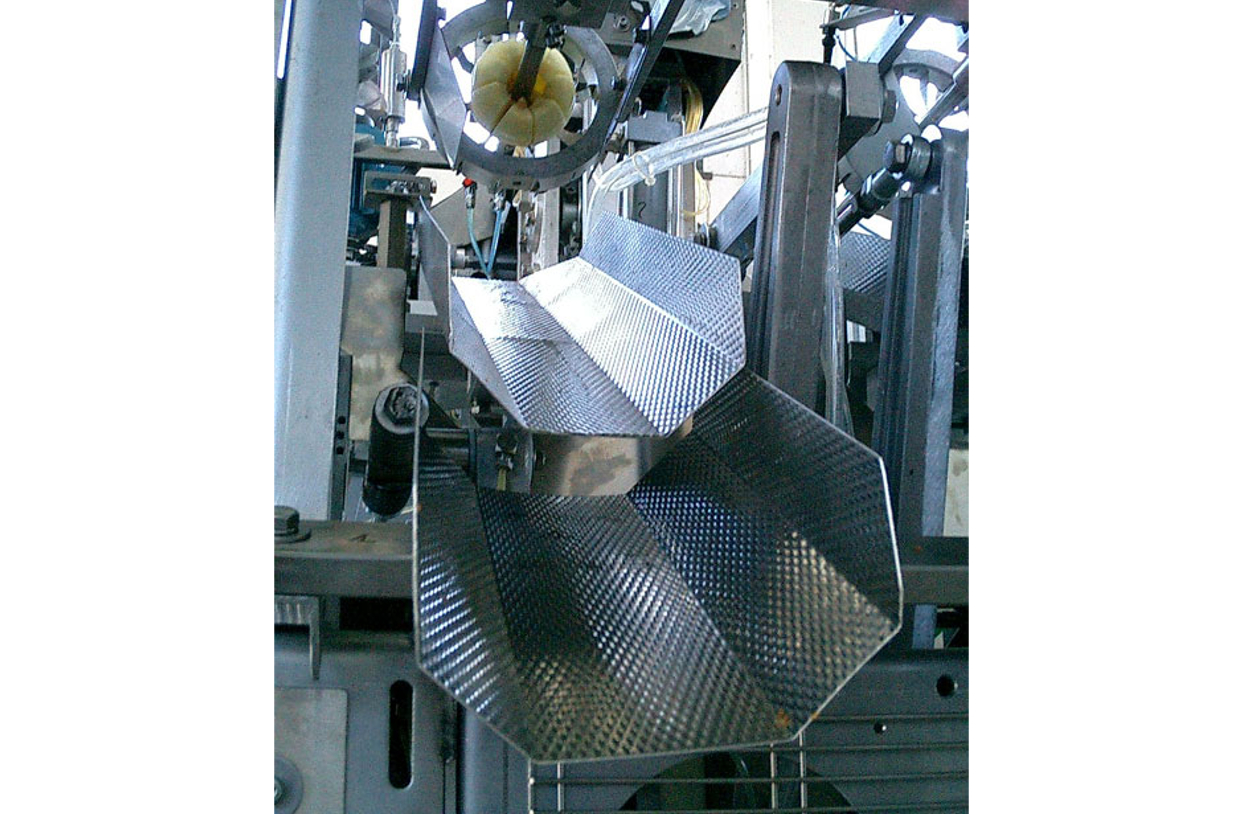

After the cut into slice apples are discharged and collected through special convoyers. When the end product is intended to be apple segments, the convoyers are replaced by stainless steel slides.

| TECHNICAL INFORMATIONS | PDS/R 25 | PDS/R 50 | PDS/R 75 | PDS/R 100 |

| Lunghezza – Length mm.Larghezza – Width mm.Altezza – Height mm. *

Peso – Weight kg. Potenza Assorbita – Power kw. Aria – Air nl/min Pressione – Pressure bar Acqua – Water L/ora Capacità oraria – Capacity/hr. kg/hr Frutti per minuto – Fruit/minute pz.

Lubrificazione automatica e ingrasso centralizzato – Automatic lub. and centralized greasing Con pompa automatica – With automatic pump *Ingombro massimo / Overall Height |

270011002500

700 1.20 180 4-5 5 150/300 25

|

270012002500

900 2.50 270 4-5 7 300/500 50

|

270015502500

1100 3.00 380 4-5 8 400/700 75

|

270017002500

1300 3.00 500 4-5 9 500/1000 100

•

|