(65) 6250 4388

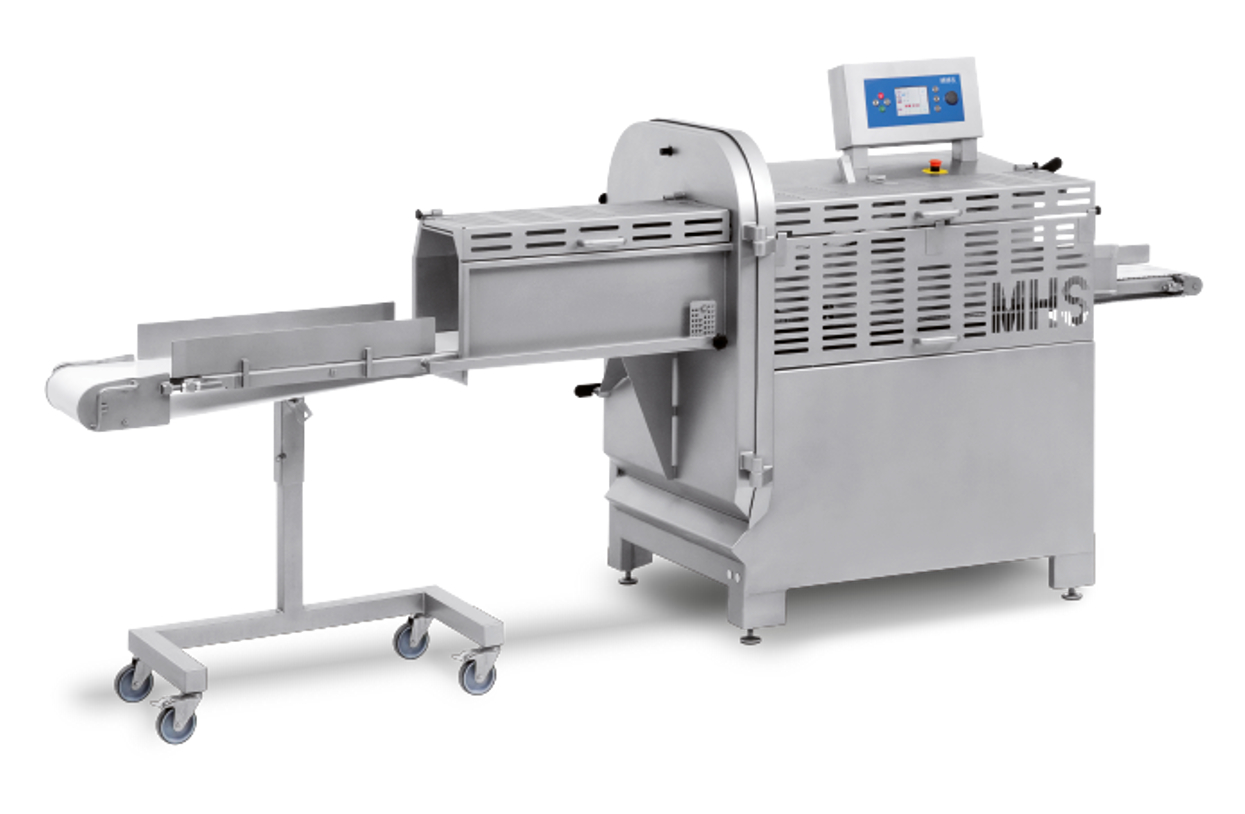

ICC 25/36

Successful. Continuous. Powerful.

PRODUCTIVITY

- Up to 500 cuts/minute (double blade 1000)

- Easy integration into production line

- Shorter cycles through continuous supply of products

- Starting device

HANDLING

- Easy operation by clear symbols

- Short learning curve

- Highest level of security

- Easy disassembly for cleaning all relevant parts

- Fully slated stainless stell housing

SLICING RESULT

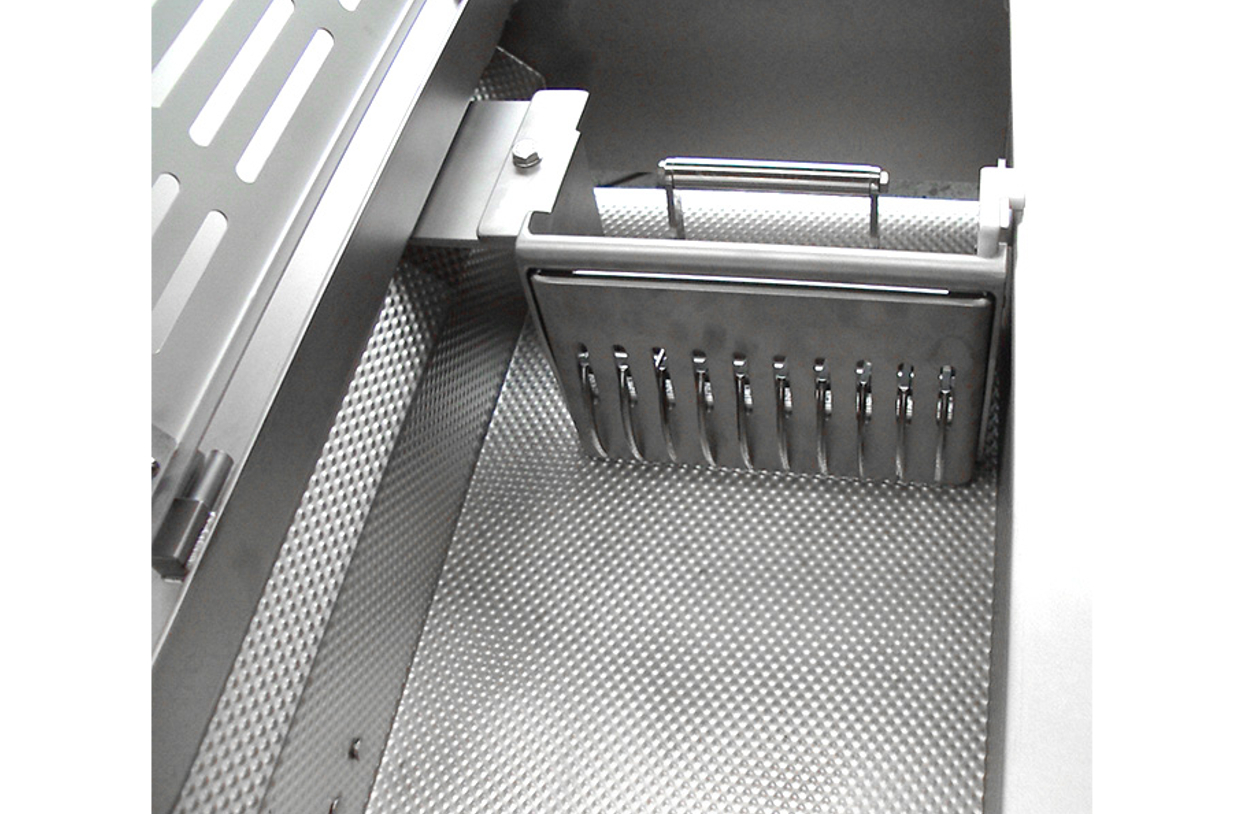

- High accuracy even with bone-in products by MHS micro-toothed blades

- Exact feed through by use of step motors

VERSATILITY

- Strong drive for bone-in products

- Different blades for additional applications such as bread or cheese (optionally available)

- Output side optional to be opened in reverse way (optionally available)

TECHNICAL DATA:

| ICC 25 | ICC 36 | |

|---|---|---|

| Max. input length (in mm) | variable | variable |

| Cross section mm (WxH) | 250 x 180 | 360 x 180 |

| Dimensions (WxDxH) in mm | 3574 x 1100 x 1620 | 3574 x 1225 x 1020 |

| Connection | 400 V / 10 kW (other voltage on request) | 400 V / 10 kW (other voltage on request) |

| Weight (in kg) | 850 | 950 |

| Performance single blade slices/minute | 60 – 500 | 60 – 500 |

| Cutting length in mm | 0,5 – unlimited | 0,5 – unlimited |

| Suitability | industry | industry |

| Start devine | yes | yes |

| Distribution of remaining slice | yes | yes |

| Slicing software | yes | yes |

| portioning | yes | yes |